The Grampaw Pettibone Squadron on March 14, 2024 meeting were privileged to be visited by Colonel Roy Martin, USAF (ret). Roy was the Chief Test Pilot for Northrop Grumman Western Region. He has over 45 years flying experience with over 10,000 flight hours in over 70 aircraft types. His combat experience includes 200 combat hours in Southeast Asia in the F-4 Phantom and additional military operational pilot experience in the F-5 and C-141.

As a test pilot, our speaker was a distinguished graduate of the USAF Test Pilot School in 1975 and demonstrated his skills as a military test pilot in E-3A AWACS, F-5 Spin tests, Air Launch Cruise Missile Development and Space Shuttle Handling Qualities Tests. Drawing from this experience, Roy was a USAF Test Pilot School Instructor.

Our speaker continued his flight test career upon leaving the Air Force and became an Engineering Test Pilot for Northrop Grumman in 1982. As a Civilian Test Pilot, Roy conducted flight tests in F-5, F-20, QF-86, Sabreliner, G-II, King Air, Cessna 206, Cessna 208, Cessna O-2A, and Firebird test aircraft. He was an Unmanned Vehicle Operator for X-47A Pegasus and Lead Test Pilot for Design of Command and Control Displays for the X-47B. His career and experience were recognized by his peers when selected as a Fellow and Past President of the Society of Experimental Test Pilots.

Speaking to the ANA Grampaw Pettibone Squadron, Colonel Martin shared his experience regarding ‘First Flight Anomalies’ occurring during buildup and test flight execution of both manned and unmanned aircraft. The anomalies in question relate to events not directly associated with aircraft performance. Issues will include foreign object damage, communication, coordination, telemetry and systems malfunctions.

The presentation was a compilation of research and documented, ‘First Flight’ events conducted by a number of different organizations and personnel who shared their findings with the speaker.

The first example concerned FOD (Foreign Object Debris) from being ingested into systems within early testing of the Northrop Grumman B2 Bomber. Technicians were instructed to wear new test suits when accessing fuel tanks to prevent material from collecting inside the tank. During ground test, fuel pump issues did take place. The cause was determined to be lint and material from the new suits which blocked the fuel filter and sump system inside the fuel tanks. The resolution was to inspect the aircraft after every dynamic event, every taxi event and remove all lint and other material collected in fuel cells. Additionally, the new suits were no longer being worn and over time the problem was controlled and tests proceeded without interruption from this issue.

Our speaker introduced a second example of FOD exposure. During a test launch of a cruise missile, the control room monitors captured altitude and track successfully. The monitors indicated the cruise missile was attempting to accelerate beyond launch speed, however, monitors appeared to indicate the speed was stuck at the launch Mach number which was slower than what the simulator numbers indicated. The chase plane pilot observed the cruise missile movement and commented that it was moving fast. As speed increased the cruise missile entered a pitch PIO (Pilot Induced Oscillation), the parachute was deployed and the missile was recovered. Post accident investigation disclosed another example of manufacturer FOD. During the flight when a zero G acceleration moment occurred, debris created during the build process drifted up and shorted out the air data transducers. When the signal failed to transmit the missile speed, the computers read the speed at launch and induced acceleration to the missile beyond the speed it was to correctly achieve.. This created the situation for a text flight failure and subsequent crash.

The next example of a flight test anomaly dealt with communication. The flight of a bomber during a test event required transmission of both audio and telemetry contact with the flight. Rather than add additional antennas, the test used existing antennas and devoted one antenna for communication and one for telemetry. The lower antenna was to address telemetry while the upper antenna was set for audio contact with the flight crew. During takeoff, all communication was lost to the outside world. The crew could communicate inside the aircraft, but could not communicate with chase aircraft or ground operations. After troubleshooting the issue, the flight crew switched the antenna’s role and was able regain audio contact. The lesson learned requires all systems to be checked before the first flight and avoid a repeat of this situation.

Communication issues can lead to other scenarios that were identified in this next event. A fighter to be tested was to be accompanied by two chase aircraft. The aircraft were to communicate on VHF with each other and UHF with the tower and other aircraft. The decision was made to launch all the aircraft from the opposite direction of normal launches. This would enable the aircraft to have access to a long lake-bed landing area in the event of an abort after launch. In addition to the opposite takeoff event, a decision to have a pilot in the control tower to assist in monitoring of aircraft movement as well as communication was agreed upon. Just prior to the launch, a B-52 was to takeoff from the same runway. Instead of letting the B-52 launch and create unstable air which could impact the test aircraft, the pilot in the control tower recommended the B-52 be held till all test and chase aircraft launched. This was a positive event and reduced any impact on the test

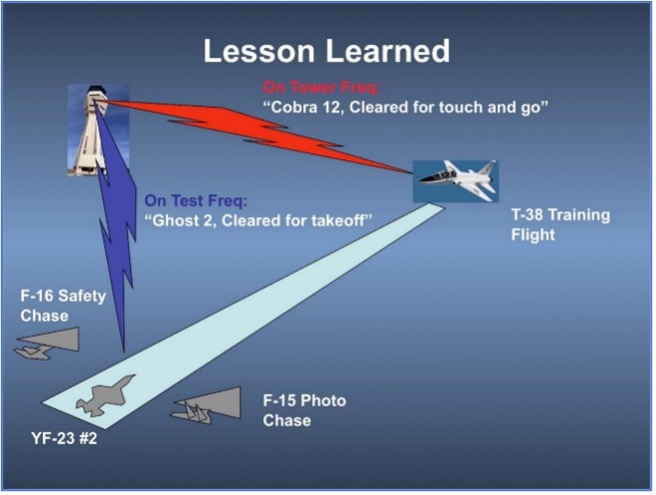

In the previous scenario, the presence of a pilot in the control tower saved the event from developing into a possible conflict and crash. However, a few months after this scenario played out, a repeat test took place. A test aircraft with a test engine and two chase aircraft were to launch from the same field in opposite direction from the then existing landing pattern. The pilots of the test were speaking to each other on a separate frequency not monitored by the tower. An aircraft already airborne was approaching the field to do a touch and go just prior to the opposite direction launch. The tower informed the pilot of the airborne aircraft of the expected opposite direction launch and to circle while waiting till all aircraft were airborne. The pilot acknowledged the request and upon observing the two-chase aircraft launch, proceeded to approach the field to land. The tower operator without a pilot observer present approved the landing only to see both chase aircraft circle the field to accompany the test aircraft about to launch. As the test aircraft launched, the landing aircraft landing from the opposite direction created a very quick movement by both pilots to avoid a mid-air collision over the field. The lack of a controlling authority to monitor all communication could have revealed the situation that was about to unfold and prevent the near miss event.

Our speaker Roy Martin continued to share his knowledge of first test flight anomalies with his next scenario. A test flight which included both audio and telemetry transmission was described. The telemetry communication utilized a low wattage transmitter during ground testing and was to switch to high wattage for communication with the control room, once airborne. The switch was needed to increase transmission range during airborne testing. As soon as the aircraft launched and the telemetry communication was switched from low to high, all telemetry was lost. The aircraft returned to land to determine the cause of the communication loss. A short was discovered in the high wattage configuration. Additional disclosure by the flight test engineer revealed during debrief that he failed to confirm communication worked with both low and high wattage communication during ground test.

One of the issues faced during a first article test is the functioning of the landing gear. Landing gear problems are very common. The next example with a fighter type aircraft occurred when the nose gear upon retraction became cocked. The gear interlocks when the gear was retracted cocked which prevented the nose gear from retracting. Discussion ensued between engineering, test flight, operations and the pilot and it was suggested to preserve the pilot, the pilot should eject from the aircraft in flight. The pilot had already tried positive ‘G’ and negative ‘G’ movements in flight to see if the nose gear would realign itself. This did not work. The pilot rather than eject from a first article flight, made the decision to return and perform a ‘touch and go’ and lightly lower the nose to see if the nose wheel would realign itself. The team agreed this was a reasonable option and the pilot executed the approach and was able to realign the nose wheel safely. The pilot then returned to land and the nose wheel issue was examined and corrected for the test to continue. Alternative actions have to be thoroughly examined to identify all options and draw from experience and capability of participating personnel to select the most appropriate choice in addressing an issue.

Another gear issue occurred with the first flight of a prototype bomber. The aircraft was equipped with an automatic gear retraction process that was to apply the breaks to the wheels as the gear was retracted and have the brakes released once the wheels were in the wheel well. The flight described in the talk did retract its gear as required, however it did not retract completely into the wheel well. The pilot released the gear to return the wheels to a down and locked position for a modified flight test. However, the pilot did not notice any issues with the gear in the down and locked position until the plane returned to land. Upon landing it was discovered the breaks were locked on both main wheels. The left side tires caught fire and the right-side tires blew, shredded and exposed the wheels to the runway surface which caused the wheels to overheat, break down and spread break and gear parts on the runway. The plane once it stopped was the subject of an emergency services response to extinguish the gear and tire fire and clean up the runway of the debris and save the aircraft from further damage.

Our speaker described another first flight event involving a nose wheel anomaly. Before any new aircraft or one modified is to be flight tested, a taxi test would be conducted. It was a common practice to include compatible legacy aircraft systems to be part of the flight test aircraft and to test out the system thoroughly before a flight launch. An existing gear system never used was installed in the test aircraft. However, during high-speed taxi testing, the aircraft experienced a sever shimmy. All efforts to troubleshoot during taxi test failed to resolve the issue. Upon returning the aircraft and shutting down the engine, it was discovered that while the gear system installed was new and unused, the unit was not current with Time Compliance Tech Orders which corrected issues discovered during installation in other aircraft. It is critical that all component systems be checked to insure they include all operational changes and corrections to avoid a similar event in future tests.

The next test to be described involved an aircraft brake system: A test pilot noted that there was a little bit of a pull in one direction during taxi testing. Sometimes, pilots do observe that the brakes wear at different rates, creating a pull or drift during brake application. It was not considered critical, according to our speaker, and it was noted as an insignificant event by the test pilot. Upon returning from the test flight, and landing on a wide runway, the test pilot noted that even with heavy braking and nose wheel steering, the plane diverted from the center line and came very close to the runway edge.

After the flight debriefing and a series of engineering tests to analyze the aircraft and onboard systems, answers were identified. The flight control test team, with the best of intentions, had installed system adjustments to counter the effects of cross-wind events during braking in roll out after landing. Without involving other members of the test team, these adjustments, created issues that led to the landing roll-out drift that otherwise would not have existed. Once the adjustments were identified and reversed, the aircraft performed as intended during landing operations.

The last issue noted dealt with the flight test team and interaction during a test. During a ground checkout prior to a first flight, Manufacturing and Flight Test Personnel were interrupting each other’s work. One-person, per shift, was given authority to coordinate and oversee all work on aircraft. Removal of extraneous visitors and non-essential personnel was ordered, to enable test personnel to continue their work uninterrupted.

First Flight Anomalies Lessons Learned

- Loss of Telemetry and Landing Gear operation failures seemed to be the largest issue.

Plan Gear Operations Early in the Flight

- FOD was an issue especially for fuel system operations and electrical component failures

- High speed taxi tests need the same safety awareness and preparation as first flight.

- Use of legacy components need updated TCTO (Tim e Compliance Technical Orders).

- One person must be in charge

The Grampaw Pettibone Squadron wishes to thank Roy Martin for sharing his knowledge and experience associated with flight test operations.